Why Forged Steel Strainers are the Best Choice for Your Pipeline System

Have you ever wondered how to ensure that your pipeline system is working efficiently and effectively? One of the key components in any pipeline system is a strainer, which helps remove debris and impurities from the flowing liquid or gas. But not all strainers are created equal! Forged steel strainers stand out as the best choice for your pipeline system due to their durability, strength, and performance. In this blog post, we’ll dive into what forged steel strainers are, how they work, and why they’re an excellent investment for your infrastructure. So let’s get started!

What are forged steel strainers?

Forged steel strainers are a type of industrial filtration device used in pipeline systems. They are designed to remove unwanted solids, debris, and other particles from liquids or gases that pass through the pipeline. These strainers can be found in various industries such as chemical processing plants, petroleum refineries, power generation facilities and more.

The main component of forged steel strainer is its body which is made up of forged carbon steel material. The forging process makes the material stronger by aligning the grain structure resulting in increased durability and resistance against corrosion.

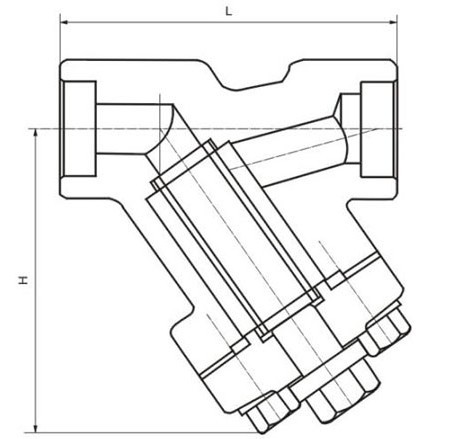

Forged steel strainers come in different shapes and sizes to fit specific piping requirements. Some common types include Y-type, T-type, basket type etc., each with its own unique design features for maximum efficiency.

Unlike other materials like cast iron or plastic which can crack under pressure or temperature changes; forged steel has high tensile strength allowing it to withstand extreme conditions without breaking down or suffering damage.

Forged Steel Strainers are heavy-duty filtering devices used across a range of industries with varying system requirements. Their durable construction allows them to effectively filter out impurities while maintaining their structural integrity over time.

How do they work?

Forged steel strainers are designed to remove unwanted debris and particles from fluid flow in pipeline systems. These strainers work by using a mesh or perforated screen that captures the impurities within the fluid stream.

The fluid enters through the inlet of the strainer and then flows through a screen or mesh, which traps any solid particles present in it. The filtered fluid then passes out through an outlet, leaving behind only pure liquid.

One of the benefits of forged steel strainers is their ability to handle high-pressure applications. Due to their strength and durability, they can withstand high flow rates without getting damaged easily.

Another advantage of these types of strainers is that they require minimal maintenance. Once installed correctly, they can operate continuously for long periods without requiring any attention or repair work.

Forged steel strainers offer effective filtration performance with low maintenance requirements making them an ideal choice for use in various industries such as oil & gas, chemical processing, water treatment plants among others.

Why are they the best choice for your pipeline system?

When it comes to maintaining a pipeline system, choosing the right components is crucial. One of the key components in any pipeline system is a strainer, which helps to remove unwanted debris and particles from the flow of liquid or gas. There are many different types of strainers available on the market today, but forged steel strainers stand out as one of the best choices for your pipeline system.

One reason why forged steel strainers are an excellent choice is their durability. They are made by heating and shaping raw materials into strong shapes through forging techniques. This process creates a stronger material that can withstand high levels of pressure and corrosion compared to other types like cast iron or plastic.

Another advantage of using forged steel strainers is their reliability. The tight seals used in these components keep debris from entering downstream systems while allowing efficient fluid flow without unnecessary resistance. It means that they can operate with minimal maintenance for extended periods, making them cost-effective over time.

Additionally, they also offer versatility when it comes to handling fluids with varying temperatures and pressures due to its toughness properties.

All in all, choosing the right type of strainer for your pipeline system will be dependent upon various factors such as pipe size and flow rate; however, if you’re looking for longevity combined with efficiency at an affordable price point – then going for forged steel strainers would be a wise decision indeed!

Forged steel strainer installation and maintenance tips

When it comes to installing and maintaining your forged steel strainer, there are a few tips that can help ensure its longevity and effectiveness. First and foremost, make sure that the strainer is installed correctly according to the manufacturer’s instructions. This includes ensuring proper alignment, gaskets, bolts or nuts torqued properly, and flanges tightened evenly.

Regular maintenance is also crucial for optimal performance of your forged steel strainer. It is recommended to inspect the strainer periodically for any damage or wear and tear on internal components such as baskets or screens. If any defects are found during inspection, they should be addressed immediately to prevent further damage.

Cleaning your forged steel strainer regularly will also help maintain its efficiency over time. Depending on the type of fluid being filtered through the system, cleaning intervals may vary. However, it is generally recommended to clean out debris from baskets or screens at least once a week.

In addition to regular inspections and cleaning routines, it’s important to keep accurate records of maintenance activities performed on your forged steel strainers. These records can be invaluable in tracking overall system health over time while identifying potential issues before they become major problems.

By following these simple installation and maintenance tips for your forged steel strainers you can help ensure their longevity while keeping your pipeline systems running efficiently without interruption!

Conclusion

As we have seen, forged steel strainers are an essential component for any pipeline system. They offer numerous benefits over other types of strainers, including durability, corrosion resistance, and high efficiency.

The use of a forged steel strainer in your pipeline system can help protect downstream equipment from damage caused by debris or foreign objects. This will reduce maintenance costs and extend the life of your equipment.

When it comes to installation and maintenance, proper handling is crucial to ensure optimal performance. Take care when installing the strainer to prevent damage during transportation or installation. Regular cleaning and inspection are also necessary to maintain its effectiveness over time.

Choosing a forged steel strainer for your pipeline system is a wise investment that offers long-term benefits in terms of cost savings and improved performance. Contact your trusted supplier today to learn more about how you can upgrade your current filtration system with this innovative technology.