Are you familiar with bellow seal globe valves? If not, then this is the perfect article for you! Bellow seal globe valves are a type of valve that is commonly used in industrial applications. They offer several advantages over other types of valves, including better sealing and increased durability. In this blog post, we will explore what below seal globe valves are, how they work, their pros and cons, and how to choose the right one for your needs. So let’s dive in and discover everything there is to know about these fascinating devices!

What is a bellow seal globe valve?

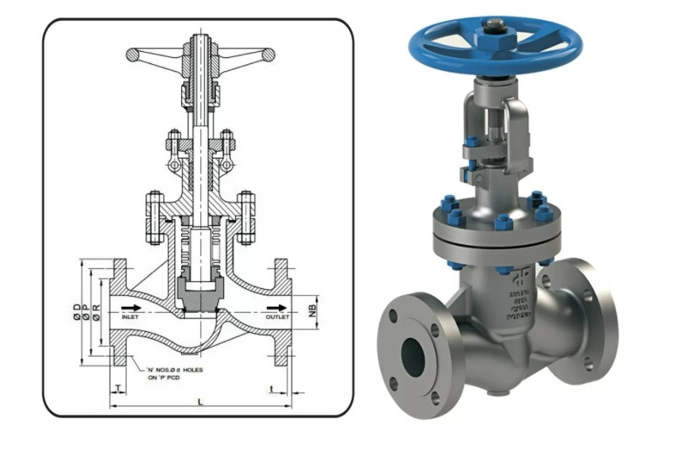

A bellow seal globe valve is a type of valve that is commonly used in industrial applications. It consists of two main components: the body and the bonnet. The body contains the valve’s internal mechanism, which controls the flow of fluid through it, while the bonnet covers and protects this mechanism.

What sets bellow seal globe valves apart from other types of valves is their use of a bellows to provide a leak-proof seal between the stem and body. This bellows acts as a barrier against external contaminants like dust or dirt, ensuring that no harmful substances enter into your system.

The operation of a bellow seal globe valve involves rotating its handwheel to open or close its gate. As you turn this wheel clockwise or counter-clockwise, you’ll see an increase or decrease in flow rate respectively.

In addition to being highly reliable and durable, bellow seal globe valves offer several advantages over other types of valves such as reduced maintenance requirements and increased safety for personnel working near them.

If you’re looking for a high-performance valve that can handle tough conditions while providing consistent results over time then look no further than bellow seal globe valves!

How does a bellow seal globe valve work?

A bellow seal globe valve is a type of control valve that works by regulating the flow of fluid through a pipe. It consists of a body, bonnet, stem, disc and bellow assembly. The body houses the internals while the bonnet provides closure for the internal components.

The stem connects to the handwheel or actuator on the top of the valve which controls its movement. When in use, this movement allows for precise regulation of fluid flow through an opening in the disc located inside.

The bellow assembly is what sets this type of globe valve apart from others. It’s designed with multiple layers and types of materials to ensure there are no leaks even when exposed to high-pressure environments or extreme temperatures.

When pressure builds up inside a pipeline, it pushes against both sides of the bellows causing them to expand which results in compression between two discs within each part creating a tight seal that prevents any leakage from occurring.

Understanding how a bellow seal globe valve operates requires knowledge about its various parts including its unique bellow assembly as well as how these different parts work together seamlessly allowing for optimal performance under demanding conditions.

What are the advantages of a bellow seal globe valve?

Bellow seal globe valves have become increasingly popular in various industries due to their numerous advantages. One of the most significant benefits is their ability to prevent leaks, making them ideal for applications where leakage can be hazardous or costly.

Another advantage of bellow seal globe valves is their durability and reliability. These valves are designed to withstand high temperatures and pressures, as well as corrosive materials commonly found in industrial settings. They also require minimal maintenance compared to other types of valves.

Bellow seal globe valves also offer excellent control over flow rate and direction, making them suitable for a wide range of applications. Their design allows for precise adjustments that make it easy to regulate the flow of fluids without causing turbulence or pressure drops.

In addition, bellow seal globe valves are eco-friendly since they do not emit harmful gases while operating. They are also energy-efficient because they require less power than traditional valve designs.

Bellow seal globe valves provide an effective solution for controlling fluid flow while offering several advantages compared to other valve types.

What are the disadvantages of a bellow seal globe valve?

While bellow seal globe valves have many advantages, they also come with a few disadvantages that need to be considered before choosing this type of valve for your application.

One disadvantage is the cost. Bellow seal globe valves are typically more expensive than other types of valves due to their construction and materials used. This can make them less desirable if you are working within a tight budget.

Another disadvantage is the limited temperature range. Bellow seal globe valves are not suitable for extremely high or low temperatures as the bellows can become damaged or fail to function properly.

Maintenance can also be another challenge with bellow seal globe valves. The complex design means that regular inspections and maintenance may be required to ensure optimal performance and prevent leaks.

Installation can also be tricky with these types of valves due to their size and weight. Proper equipment may be required during installation which could add additional costs.

While there are some disadvantages associated with bellow seal globe valves, they still remain a popular choice in many industries due to their reliability and durability in harsh environments.

How to choose the right bellow seal globe valve for your needs?

When choosing a bellow seal globe valve, there are several important factors to consider. Firstly, you need to determine the type of fluid that will be flowing through the valve and its temperature range. This information is crucial in selecting the right material for your bellow seal globe valve.

Secondly, you need to take into account the pressure rating needed for your application. Different types of valves have varying pressure ratings and choosing one that can handle your system’s maximum operating pressure is essential.

Thirdly, consider the size of the valve required as well as any specific end connections needed for installation. It’s also important to check if it meets any industry standards or certifications required by your organization.

Think about maintenance requirements and accessibility for repair or replacement needs down the line. A high-quality bellow seal globe valve should last long with minimal maintenance but having easy access when repairs are necessary should not be overlooked.

Choosing a bellow seal globe valve may seem overwhelming at first but taking these factors into consideration will help ensure you select a product that suits all your specific needs while providing optimal performance over time.

Conclusion

A bellow seal globe valve is an excellent choice for applications that require reliable and leak-proof sealing. It offers many advantages over other types of valves, including durability, versatility and low maintenance requirements. However, it also has some disadvantages to consider before making your purchase.

When choosing the right bellow seal globe valve for your needs, be sure to consider factors such as material compatibility, pressure rating, temperature range and size requirements. It’s crucial to choose a valve that will meet all your specific needs while providing reliable performance for years to come.

A bellow seal globe valve is an excellent investment in any system where tight shutoff and superior sealing are essential. With proper selection and installation by a professional technician or engineer familiar with this type of product line-up – you can have peace of mind knowing that you’ve made the right decision when it comes to choosing the best quality product on the market today!