Whether you’re involved in the oil and gas industry, chemical processing, or any other application that requires precise control of fluid flow, cast steel floating ball valves are an essential component. These high-performance valves offer a range of advantages over other types of valves, including durability, reliability, and ease of use. In this article, we’ll explore what cast steel floating ball valves are and how they work. We’ll also look at the different types of cast steel floating ball valves available on the market today and their best applications. So let’s dive in!

What is Cast Steel Floating Ball Valves?

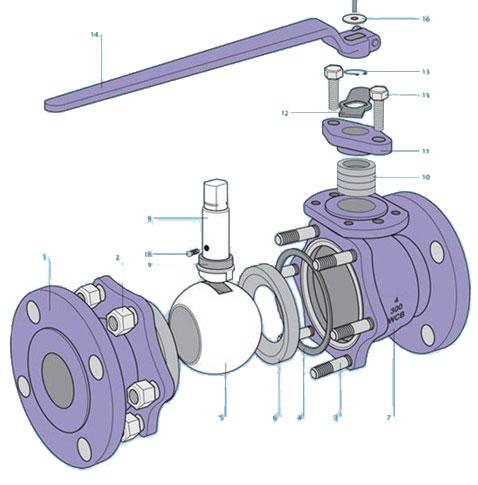

Cast steel floating ball valves are a type of valve that is commonly used in industrial applications for controlling the flow of fluids. These valves consist of a hollow sphere (the ball) with an opening through which fluid can pass. The ball is attached to the valve stem, which rotates to open or close the valve.

One of the key advantages of cast steel floating ball valves is their durability. They are constructed from high-quality materials such as stainless steel or carbon steel, making them resistant to corrosion and wear.

Another advantage of these valves is their ease of use. Cast steel floating ball valves require very little force to operate, and they can be easily opened or closed using a simple lever or handle.

Cast steel floating ball valves come in different types depending on their design and features. Some common types include two-piece, three-piece, top-entry, and flanged-end cast steel floating ball valves.

Cast steel floating ball valves offer numerous benefits over other types of valves and are an ideal choice for many industrial applications where precise control over fluid flow is required.

Advantages of Using Cast Steel Floating Ball Valves

Cast steel floating ball valves are a popular choice among various industries due to their many advantages. One of the key benefits is the valve’s ability to provide tight sealing, which ensures that there are no leakages or seepages from the system. This feature makes these valves ideal for use in pipelines and other systems where fluid control is essential.

Another advantage of cast steel floating ball valves is their durability. Made with high-quality materials, these valves can withstand harsh environments and tough conditions without losing performance capabilities. Their robust design also ensures that they require little maintenance, reducing downtime and repair costs.

Cast steel floating ball valves also offer excellent flow control capabilities. With a simple turn of the handle, users can easily regulate liquid or gas flow through the pipe system accurately. Additionally, these types of valves have low torque requirements compared to other valve types, making them easy to operate even at high pressure levels.

Cast steel floating ball valves are versatile enough to handle different applications effectively. They come in various sizes and configurations suitable for both general-purpose and specific industry needs such as petrochemicals processing plants or oil refineries.

Using cast steel floating ball valves offers several advantages that promote efficient and reliable operation while minimizing cost implications associated with repairs and replacements over time.

The Different Types of Cast Steel Floating Ball Valves

Cast steel floating ball valves come in various types, each designed to cater to specific needs. Here are some of the different types of cast steel floating ball valves:

- Two-piece body type – This type of valve has two separate pieces that are bolted together, making it easy to disassemble and maintain.

- Three-piece body type – The three-piece design allows for easier maintenance and repair as you can easily remove the center section without disturbing the piping connections.

- Top entry type – With this type of valve, the top cover is removable, allowing access to internal parts for maintenance or replacement without removing it from the pipeline.

- Flanged end connection type – This is a common valve with a flange welded on both ends that connects directly onto pipelines carrying fluids such as water and steam.

- Butt-weld end connection type – Suitable for high-pressure applications requiring a permanent weld between pipe and valve ends.

It’s essential to select the right cast steel floating ball valve based on your application requirements, including pressure ratings, fluid compatibility, temperature ranges, among others.

How to Use Cast Steel Floating Ball Valves

Using cast steel floating ball valves is a simple task, but it requires proper knowledge and understanding of the valve’s features. Firstly, ensure that the valve is installed correctly according to its orientation, which should be indicated by an arrow on the body. This will prevent any potential damage to the valve or pipeline.

Next, open or close the valve by rotating its handle in either direction. The position of the handle indicates whether the valve is fully open or closed – parallel to the pipeline means open while perpendicular means closed.

It’s essential to operate cast steel floating ball valves smoothly and avoid sudden movements that may cause damage. Furthermore, consider factors such as temperature and pressure when using these valves. Ensure they are not subjected to pressures beyond their maximum allowable limit.

Regular maintenance checks are necessary for optimal performance of your cast steel floating ball valves. Proper lubrication and cleaning go a long way in increasing their lifespan and preventing premature wear and tear.

By following these simple steps when using cast steel floating ball valves, you can ensure efficient operation without causing any damage or issues with your pipelines.

When to Use Cast Steel Floating Ball Valves

Cast steel floating ball valves are versatile and can be used in various applications. One of the main factors to consider when deciding whether to use a cast steel floating ball valve is the fluid or gas being transported.

In high-pressure and high-temperature situations, such as in chemical plants or oil refineries, cast steel floating ball valves are often preferred due to their durability and ability to withstand extreme conditions.

They are also commonly used in pipelines carrying natural gas, crude oil, and other corrosive fluids because they have a low risk of leakage and can handle large volumes of flow.

Another situation where cast steel floating ball valves may be useful is when there is a need for frequent operation. Their simple design makes them easy to operate manually or with automation equipment.

When choosing whether to use cast steel floating ball valves, it’s important to consider the specific needs of your application. Factors like pressure, temperature, fluid type and frequency of operation will help determine if these types of valves are the best choice for your project.

Conclusion

To sum up, cast steel floating ball valves are an excellent choice for various industries due to their durability and versatility. They offer several advantages over other valve types, including reliable sealing, low torque operation, and ease of maintenance.

When selecting a cast steel floating ball valve, it is crucial to consider the specific application requirements and choose the appropriate type accordingly. Additionally, proper installation and regular maintenance can help ensure optimal performance and prolong the lifespan of these valves.

By utilizing cast steel floating ball valves in your operations, you can enhance efficiency while reducing downtime and maintenance costs. So why not invest in this cost-effective solution today?