The Advantages of Using a Pneumatic Titanium Ball Valve

Are you in search of a valve that can withstand harsh environments and extreme temperatures? Look no further than the pneumatic titanium ball valve. This high-performance valve is becoming increasingly popular due to its many advantages over traditional valves. From improved durability to increased efficiency, there are numerous reasons why the pneumatic titanium ball valve should be your go-to choice for industrial applications. In this article, we’ll explore what makes this innovative technology so special and how you can select the right one for your specific needs. So let’s dive into the world of pneumatic titanium ball valves!

What is a pneumatic titanium ball valve?

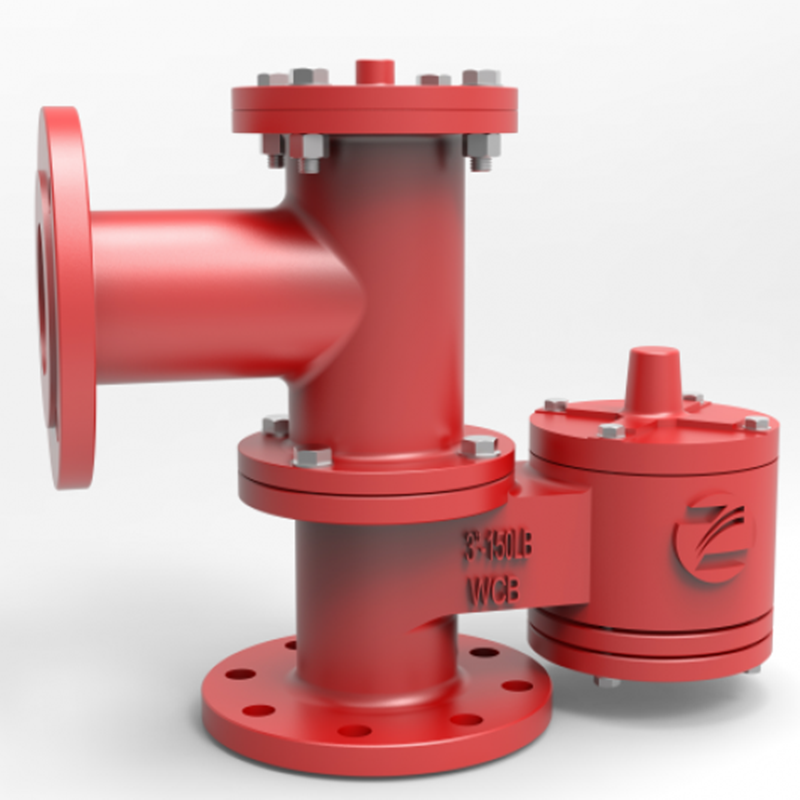

A pneumatic titanium ball valve is a type of valve that controls the flow of fluids or gases. It uses a spherical ball with a hole in the center to control and direct the flow through the valve. When turned 90 degrees, this ball rotates inside its housing, either opening or closing off the flow.

What sets apart pneumatic titanium ball valves from other types is their construction material. As their name suggests, they are made of high-quality titanium which has exceptional resistance to corrosion and extreme temperatures. The result is a highly durable and reliable valve that can withstand harsh environments like those found in chemical processing plants and power generation facilities.

Pneumatic titanium ball valves also use compressed air to operate, allowing them to open and close quickly without needing electricity or manual force. This makes them an excellent choice for industrial applications where speed and efficiency are essential.

Pneumatic titanium ball valves offer numerous advantages over traditional valves, making them an ideal option for many industries that require precise fluid control at high pressures or temperatures.

What are the advantages of using a pneumatic titanium ball valve?

A pneumatic titanium ball valve is a type of valve that uses compressed air to control its opening and closing. This type of valve has several advantages over other types of valves, including durability, corrosion resistance, and ease of maintenance.

One advantage of using a pneumatic titanium ball valve is its durability. Titanium is an incredibly strong material that can withstand high pressure and temperature conditions without cracking or breaking. This means that the valve will last longer than other types of valves, reducing the need for costly replacements.

Another advantage is their superior corrosion resistance. Titanium has excellent resistance to chemical attack and won’t corrode easily like other metals such as steel or brass would in harsh environments. Additionally, it’s capable of withstanding exposure to saltwater which makes it ideal for marine applications.

Ease-of-maintenance also sets this type of valve apart from others on the market. The design allows quick access for cleaning or replacement if necessary – minimizing downtime when working with these valves in industrial settings.

Pneumatic titanium ball valves are much safer than manual ones because they don’t require human intervention to operate – this reduces risk associated with human error during operation making them perfect options where safety concerns are paramount .

These benefits make pneumatically operated titanium ball valves popular choices in various industries ranging from water treatment plants to power generation facilities where reliable performance under harsh conditions is necessary.

Why are pneumatic titanium ball valves becoming more popular?

Pneumatic titanium ball valves are becoming more popular for several reasons. One of the main reasons is because they offer superior resistance to corrosion and erosion, making them ideal for use in harsh environments such as chemical processing plants and offshore oil rigs.

Another reason why these valves are gaining popularity is that they are highly durable, which means they can withstand high-pressure applications without leaking or failing. This makes them a reliable choice for industries where safety and reliability are paramount.

In addition to their durability and corrosion-resistance, pneumatic titanium ball valves also offer excellent flow control capabilities. With a simple turn of the handle or flip of a switch, operators can adjust the valve’s position to regulate fluid flow rates accurately.

Moreover, pneumatic titanium ball valves also require minimal maintenance due to their robust construction and self-cleaning properties. They don’t easily get clogged by debris or contaminants like other types of valves do, reducing downtime caused by valve blockages.

It’s clear why pneumatic titanium ball valves have been increasingly popular lately: They provide long-lasting performance in demanding applications while requiring minimal maintenance efforts over time.

How to select the right pneumatic titanium ball valve for your needs

When it comes to selecting the right pneumatic titanium ball valve for your needs, there are a few factors you should take into consideration. Firstly, you need to determine the size of the valve that is suitable for your application. The size will depend on various factors such as the flow rate and pressure of the fluid or gas passing through it.

Another important factor to consider is the type of actuator required for your application. Pneumatic actuators are popular due to their reliability and ease of use, however other options such as electric or hydraulic may be more suitable depending on your specific needs.

It’s also essential to consider the temperature and chemical compatibility requirements when choosing a pneumatic titanium ball valve. Titanium has excellent corrosion resistance properties, but certain chemicals or extreme temperatures may require special coatings or materials.

You’ll want to ensure that you select a reputable manufacturer with experience in producing high-quality valves. Look for certifications such as ISO 9001:2015 which indicates adherence to quality management standards.

By taking these considerations into account when selecting a pneumatic titanium ball valve, you can ensure optimal performance and longevity from your investment.

Conclusion

A pneumatic titanium ball valve is an excellent choice for any industry that requires precision and durability in fluid control applications. Its unique features like corrosion resistance, high strength, lightweight construction, reliable performance, and low maintenance requirements make it suitable for various industries such as chemical processing, oil and gas production, pharmaceuticals manufacturing, water treatment facilities among others.

When selecting a pneumatic titanium ball valve for your application needs; consider factors such as operating pressure range and temperature range compatibility with the fluids being transported through it. Also ensure to purchase from reputable manufacturers or suppliers who can provide quality valves that meet industry standards.

In summary using a pneumatic titanium ball valve enhances operational efficiency while reducing downtime attributed to regular maintenance needs. It provides long-term cost savings by eliminating frequent replacements due to wear and tear compared to other materials used in constructing valves.

All in all choosing a pneumatic titanium ball valve will undoubtedly be the best decision you will ever make when seeking durable solutions to your fluid control challenges.