Pressure Seal Globe valves are a common sight in manufacturing and construction. They’re typically used to control the flow of liquids, gases, or soils. But what do you need to know about pressure seal globe valves?

In this blog post, we will discuss the different types of pressure seal globe valves, their applications, and how they work. We’ll also give you tips on how to choose the right valve for your needs. Finally, we’ll provide a guide on how to install a pressure seal globe valve.

What are Pressure Seal Globe Valves?

Pressure seal globe valves are used to control the flow of liquids, gases, and steam. They are inserted into the piping system and can be opened and closed to control the pressure in the system.

How Does Pressure Seal Globe Valves Work?

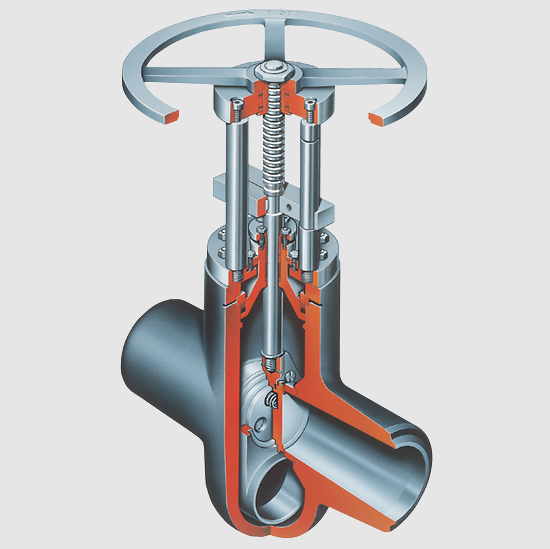

A pressure seal globe valve is a type of valve that creates a quick, tight seal between two surfaces by using the pressure of air or water flowing through it. Globes are typically made from metal and have small holes in them. When the air or water pressure is greater than the atmospheric pressure, the small holes close, stopping the flow of fluid. The advantage to this type of valve is that it can create a tight seal between two surfaces quickly and easily.

The downside to this type of valve is that it can be difficult to repair if something goes wrong. If there is a leak in the system, for example, fluid may seep past the seals and damage other parts of the system. Additionally, because globes are made from metal, they can rust if not properly cared for.

Benefits of Pressure Seal Globe Valves

Pressure seal globe valves come in a variety of types and sizes to suit just about any application. They are typically used in industrial and commercial settings, where high-pressure fluids need to be maintained under pressure. Globe valves have several benefits that set them apart from other types of valves. These include:

1. Globe Valves Are Durable:

Globe valves are made from heavy gauge metal bars that are welded together. This makes the valve very durable and resistant to wear and tear. In addition, the globe design prevents dirt, debris, and gases from entering or escaping the valve. This makes the valve more reliable in high-pressure applications.

2. Globe Valves Are Easy To Use:

Globe valves come with easy-to-use installation instructions that make it easy to install the valve correctly the first time. Most do not require any special tools or skills, making them ideal for use in commercial settings.

3. Globe Valves Have Low Maintenance Requirements:

Unlike traditional ball valves, globe valves do not require regular oiling or cleaning. Because they are made from heavy gauge metal, they will only require inspection and maintenance if there is any sign of wear or damage.

What Kinds of Pressure Seal Globe Valves are Available?

There are a few types of pressure seal globe valves available on the market, each with its own unique features and benefits.

Here is a breakdown of each type:

Spring-loaded: These valves are typically spring-loaded to help prevent accidental closure. They also have a built-in indicator light that let you know when the valve is open or closed.

Piston: Piston valves are typically activated by pressing down on the top. This makes them good for applications that require manual operation, like water filtration systems.

Rotary: Rotary valves are typically used in high-pressure applications where precision is key, like oil and gas wells. They have a rotating disk that helps to create a seal between the valve and the pipe.

Which Globe Valves are Suitable for My Application?

There are a few things you need to know before selecting a globe valve for your application. First, the type of liquid you are working with is important. Globe valves are designed for use with liquids and gas, but they may not be suitable for other applications. Second, the size of the valve is also important. Globe valves come in a variety of sizes to fit most applications. Finally, make sure to select a globe valve that is compatible with your system.

When selecting a globe valve for your application, it is important to consider the type of liquid you are working with and the size of the valve. Globe valves come in a variety of sizes to fit most systems. The types of liquids that Globe valves are designed for include: liquids and gas, but they may not be suitable for other applications.

Another factor to consider when selecting a globe valve is compatibility. Make sure to select a globe valve that is compatible with your system by checking the specifications on the product page or contacting the manufacturer directly.

How to Check if Your Globe Valve is Leaking

If your globe valve is leaking, you may notice water spilling out of the valve and onto the floor. You can check if your globe valve is leaking by following these steps:

1) Shut off the power to your home.

2) Remove any plugs from the valves that you will be checking.

3) Open each valve slowly and carefully, allowing the water to flow into a bowl or container. If water is spilling out of one or more valves, it is likely that your globe valve is leaking and needs to be replaced.

How to Fix a Leaking Globe Valve

Leaking Globe Valves: What You Need To Know

A leaking globe valve can be a frustrating problem, particularly if it’s not fixed quickly. Here are five things to keep in mind if you suspect your globe valve is leaking:

1. Check the condition of the O-ring. If the O-ring is dry, brittle, or cracked, it may be failing and need to be replaced. If the O-ring seems OK but you still see liquid seeping out, you may need to replace the globe valve itself.

2. Make sure there’s no obvious damage to the stem or seal surrounding the valve body. Damage here could result in leaks.

3. Turn off the power to the system and check for any obvious obstructions that might be preventing water from flowing freely through the valve (e.g., clogged screens, and debris). Once cleared, turn on the power and test for leaks again.

4. If all else fails and you still see liquid seeping out of your globe valve despite following steps 1-3, it might be necessary to replace the valve entirely. Verify this by removing the old valve and testing for leaks; if they’re still present, you’ll need to replace the entire unit.]]>

How to choose the right pressure seal globe valve for your needs

Picking the right pressure seal globe valve for your needs can be a daunting task, especially if you’re not familiar with the different types available. In this blog post, we’ll take a look at some of the key factors to consider when choosing a globe valve, and provide tips on how to choose the best one for your needs.

When looking at pressure seal globe valves, the most important factor to consider is the application it will be used in. There are several different types of applications that these valves can be used in, including:

Piping: Globe valves are typically used in piping systems to create a tight seal between two pieces of equipment. They can also be used as stopcock valves or check valves.

: Globe valves are typically used in piping systems to create a tight seal between two pieces of equipment. They can also be used as stopcock valves or check valves. HVAC: Globe valves are commonly found in air conditioning and heating units, and are used to control airflow and temperature.

: Globe valves are commonly found in air conditioning and heating units and are used to control airflow and temperature. Water treatment: Globe valves are often found in water treatment plants, where they’re used to open/close water lines simultaneously or sequentially.

: Globe valves are often found in water treatment plants, where they’re used to open/close water lines simultaneously or sequentially. Gas networks: Globe valves are also frequently found in gas networks,

Conclusion

If you are in the market for pressure seal globe valves or want to learn more about them, read on. In this article, we’ll cover what pressure seal globe valves are, what use they have, and some of the things you need to know before purchasing one. We hope this provides you with everything you need to make an informed decision about buying a pressure seal globe valve.