Are you looking for a reliable and efficient way to control the flow of fluids in your industrial processes? Look no further than nickel plug valve! These specialized valves are designed to offer superior performance and durability, making them an excellent choice for a wide range of applications. In this blog post, we’ll explore what nickel plug valves are, their benefits compared to other types of valves, how to choose the right valve for your needs, and where to find high-quality options. So let’s dive into the world of nickel plug valves!

What are nickel plug valves?

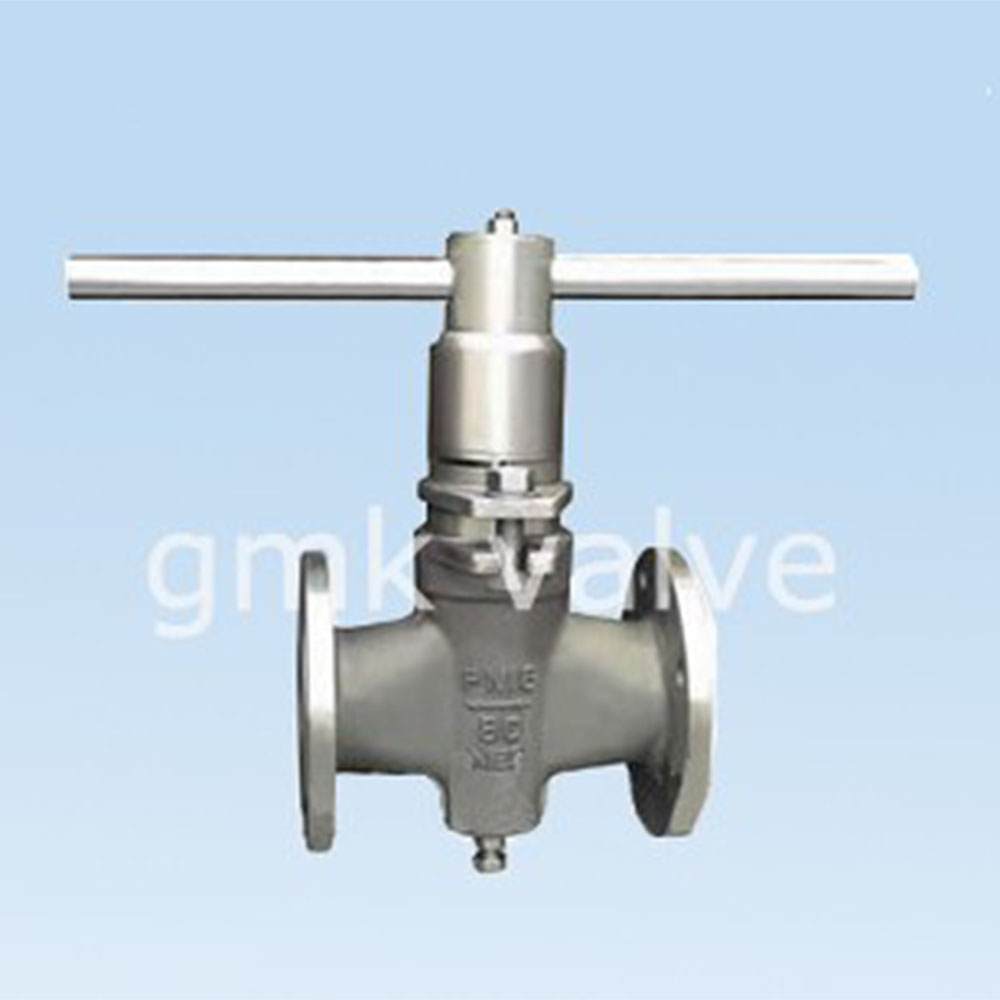

Nickel plug valves are a type of industrial valve used to control the flow of fluids in various processes. Their unique design features a cylindrical or tapered plug that fits snugly into the valve body, with an opening through which fluid can pass. The plug is typically rotated by a handle or actuator to regulate the flow rate.

One key advantage of nickel plug valves is their ability to provide precise and repeatable flow control, even in high-pressure and high-temperature applications. They also offer excellent resistance to corrosion, wear, and abrasion due to their nickel-based construction materials.

There are two main types of nickel plug valves: lubricated and non-lubricated. Lubricated models use a small amount of grease or oil on the sealing surfaces for improved sealing performance, while non-lubricated options rely on metal-to-metal contact between the plug and valve body.

Nickel plug valves are a versatile and reliable solution for industries ranging from petrochemicals to food processing. With proper selection and maintenance, these specialized valves can help ensure efficient operation and maximize process uptime.

The benefits of nickel plug valves

Nickel plug valves offer a range of benefits that make them an ideal choice for flow control applications in various industries. First and foremost, nickel plug valve suppliers are highly resistant to corrosion and can withstand harsh environments, including those with high temperatures and pressures. This makes them an excellent option for use in chemical processing plants, oil refineries, and other similar settings.

Another benefit of nickel plug valves is their relatively simple design. With fewer moving parts than other types of valves, they require less maintenance over time which reduces operating costs. Additionally, the tight seal achieved by these valves ensures effective flow control with minimal leakage.

Nickel plug valves also allow for precise adjustment of the flow rate thanks to their quarter-turn operation mechanism. This means that operators can quickly open or close the valve as needed without having to turn it multiple times or fiddle with any complicated settings.

Nickel plug valves provide reliable performance in demanding conditions while being easy to maintain and operate efficiently. For these reasons alone, they’re often preferred over other types of conventional controls such as ball or gate valves when accuracy is key to successful operations management.

Why nickel plug valves are the best choice for flow control

Nickel plug valves are the best choice for flow control because of their superior durability and reliability. These valves are constructed from high-quality nickel alloys that can withstand extreme temperatures, pressures, and corrosive environments. This makes them ideal for use in industries such as oil & gas, chemical processing, power generation, and more.

Unlike other types of valves that may wear out or leak over time due to exposure to harsh conditions, nickel plug valves offer exceptional resistance to corrosion and erosion. They have a simple yet effective design that allows for precise regulation of fluid flow with minimal maintenance required.

Another advantage of using nickel plug valves is their versatility in handling a wide range of fluids including liquids, gases, slurries, and powders. They can be used in both on/off applications or throttling services which require accurate flow control.

When selecting the right nickel plug valve for your needs it’s important to consider factors such as pressure rating requirements, temperature limitations, size constraints, and end connection options. By working with an experienced supplier you can ensure you get the right valve for your specific application needs.

Nickel plug valves provide efficient performance while reducing downtime caused by frequent maintenance or replacement costs associated with other types of valve materials. If you’re looking for reliable flow control solutions designed to maximize efficiency then look no further than nickel plug valves!

How to select the right nickel plug valve for your needs

When it comes to selecting the right nickel plug valve for your needs, there are a few key factors you’ll want to consider. First and foremost, think about the specific application in which the valve will be used. This can impact important characteristics like size, pressure rating, and temperature range.

Next, consider the flow control requirements of your system. Do you need precise control over flow rates? Or is it more important that your valve can handle high volumes of fluid or gas with ease?

Another factor to keep in mind is compatibility with other materials in your system. If your pipes or tanks are made of a certain material, you’ll want to select a nickel plug valve that won’t corrode or react negatively when exposed to those materials.

Don’t forget about cost considerations – while investing in quality equipment is always worthwhile, make sure you’re not overspending on features or capabilities that aren’t necessary for your specific application.

By taking these factors into account when selecting a nickel plug valve for your needs, you can ensure efficient and reliable flow control performance that meets all of your unique requirements.

Nickel plug valves vs. other types of valves

When it comes to flow control, there are many types of valves available in the market. However, nickel plug valves have several advantages over other types of valves.

Firstly, compared to ball valves or gate valves, nickel plug valves require less torque to operate. This means that they are easier and faster to open and close, making them ideal for applications where quick response times are needed.

Moreover, nickel plug valves offer excellent resistance against corrosion due to their high nickel content. This makes them suitable for use in harsh environments such as chemical processing plants or offshore oil rigs.

Another advantage of nickel plug valves is their compact design which makes them easy to install in tight spaces without sacrificing performance. They also provide a tight seal which reduces the risk of leakage and ensures reliable operation.

While other types of valves may be cheaper initially, they can end up costing more in maintenance expenses due to frequent replacements or repairs required. Nickel plug valves have a longer lifespan and require less maintenance overall.

While there are various types of valves available on the market today with different features and benefits; however when it comes down to reliability and efficiency at an affordable price range- Nickel Plug Valves win!

Where to find quality nickel plug valves

When it comes to finding quality nickel plug valves, there are a few things you should keep in mind. First and foremost, it’s important to work with a reputable supplier who has experience providing these types of valves. Look for companies that specialize in flow control equipment and have a proven track record of delivering high-quality products.

Another key factor to consider when looking for nickel plug valves is the materials used in their construction. Make sure the valve body and internal components are made from durable, corrosion-resistant materials like nickel or stainless steel.

In addition to the quality of the product itself, you’ll also want to pay attention to factors like pricing and customer service. While cost shouldn’t be your only consideration, it’s still important to find a company that offers competitive prices on their products.

Don’t forget about availability and lead times. If you need your nickel plug valves quickly or require custom configurations, make sure you choose a supplier who can accommodate your needs in a timely manner.

By working with an experienced supplier who prioritizes quality materials and excellent customer service, you can ensure that you’re getting reliable nickel plug valves that will perform well over time.

Conclusion

To sum it up, nickel plug valves are an excellent choice for efficient and reliable flow control. They offer numerous benefits over other types of valves, including durability, corrosion resistance, and tight shutoff capabilities.

When selecting a nickel plug valve for your application, consider factors such as temperature, pressure rating, size requirements, and the type of fluid being controlled. It’s also important to choose a reputable supplier who can provide high-quality valves that meet industry standards.

Ultimately, investing in high-quality nickel plug valves can help ensure smooth operations and reduce downtime in various industries such as chemical processing plants or oil refineries. With proper maintenance and care, these durable valves can provide long-lasting performance while improving efficiency and safety within your system.