Are you in search of a reliable valve that can withstand high-pressure and extreme temperatures? Look no further than the cast steel trunnion mounted ball valve! Known for its durability and superior performance, this valve is an excellent choice for various industrial applications. In this blog post, we’ll discuss what makes the cast steel trunnion-mounted ball valve stand out from other valves on the market and explore five of its best uses. Whether you’re a seasoned engineer or new to the industry, you’ll want to read on to learn more about this impressive piece of equipment.

What is a cast steel trunnion mounted ball valve?

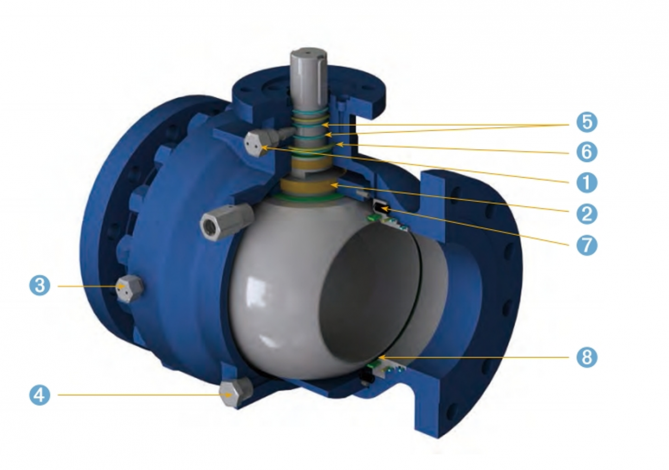

A cast steel trunnion mounted ball valve is a type of industrial valve that’s designed to regulate the flow of liquids, gases or other media in pipelines. It comprises three main components: the body, ball and stem. The body is made from cast steel and houses the internal components.

The ball inside the valve has a hole through its center, which allows fluids to pass through when it aligns with the pipeline. When turned at an angle, however, it blocks off fluid flow entirely. This mechanism makes it possible for operators to control liquid or gas flow effectively.

The stem plays a crucial role in actuating the valve – you can turn it manually or use hydraulic power to do so. Additionally, trunnions support both sides of the ball while allowing rotation movement; this ensures smooth operation even under high pressure.

What sets cast steel trunnion mounted ball valves apart from other types is their ability to handle high-pressure applications while still providing accurate control over fluid flow rates.

Why are cast steel trunnion mounted ball valves the best choice for certain applications?

Cast steel trunnion mounted ball valves are an excellent choice for certain applications due to their unique design and construction. These valves have a fixed shaft with bearings that hold the ball in place, allowing it to rotate around its axis.

One of the main advantages of cast steel trunnion mounted ball valves is their ability to handle high-pressure environments. They are commonly used in industries such as oil and gas, where they can withstand extreme temperatures and pressures.

In addition, these types of valves offer superior flow control compared to other valve designs. This is because the ball inside the valve rotates freely, allowing for precise regulation of fluid flow.

Another benefit of using cast steel trunnion mounted ball valves is their durability. The materials used in their construction are designed to withstand harsh conditions over extended periods without suffering from wear or corrosion.

These valves offer minimal friction loss during operation, meaning that there is less resistance against the fluid flowing through them. This results in improved energy efficiency for your system overall.

If you need a reliable and durable valve that can handle high-pressure environments while providing precise flow control and low friction loss, then a cast steel trunnion mounted ball valve may be just what you need.

What are the top five uses for a cast steel trunnion mounted ball valve?

Cast steel trunnion mounted ball valves are a reliable and durable choice for many industrial applications. Here are the top five uses of these valves:

- Oil and Gas Industry: Cast steel trunnion mounted ball valves are commonly used in the oil and gas industry due to their high-pressure ratings, temperature resistance, and durability.

- Petrochemicals Industry: These valves are also widely used in the petrochemicals industry because they can handle corrosive materials such as acids, alkalis, and hydrocarbons.

- Power Generation Plants: Cast steel trunnion mounted ball valves find extensive use in power generation plants where they control steam flow or coolant water that is circulated through turbines and other equipment.

- Water Treatment Plants: The ability of these valves to withstand harsh chemicals makes them an ideal choice for water treatment plants where they regulate chemical flows during various processes like disinfection or filtration.

- Mining Industry: In mining operations, cast steel trunnion mounted ball valves help control material flow throughout production processes including crushing, grinding or concentration stages.

In summary, cast steel trunnion mounted ball valve’s versatility has made it the preferred option across industries that require reliable performance under extreme conditions while reducing maintenance costs over time compared with alternative types of industrial pipeline components like gate & globe valve systems which may not provide adequate sealing solutions necessary for some applications (e.g., low pressure).

How to select the right cast steel trunnion mounted ball valve for your needs

When selecting the right cast steel trunnion mounted ball valve for your needs, there are several factors to consider. The first factor is the pressure rating of the valve that you need. Cast steel trunnion mounted ball valves come in a range of pressure ratings, so it’s important to select one that can handle the specific pressures required in your application.

The second factor to consider is the size and type of connection needed for your installation. Be sure to choose a valve with compatible connections and an appropriate size for optimal performance.

Thirdly, look at what material options are available for both the body and trim materials depending on what chemicals or media will be flowing through them.

Additionally, take into account any special requirements such as fire-safe design or cryogenic applications if needed.

Ensure that you purchase from a reputable supplier who can offer technical support throughout installation and use along with maintenance services when necessary.

Conclusion

To sum up, a cast steel trunnion mounted ball valve is an excellent choice for many applications due to its durability and reliability. Its design allows it to handle high-pressure environments and abrasive materials while maintaining tight sealing. The top five uses of this type of valve include oil and gas pipelines, petrochemical plants, power generation facilities, water treatment plants, and mining operations.

When selecting the right cast steel trunnion mounted ball valve for your specific needs, consider factors such as size, pressure rating, temperature range, material compatibility with the fluid being transported or processed, actuator type (manual or automated), and maintenance requirements.

By understanding the benefits of using a cast steel trunnion mounted ball valve in appropriate applications and carefully selecting the right one for your needs can lead to safer operation processes with low risk of leakage or failure.