Double block and bleed ball valve are essential components in many industrial processes. They offer a reliable solution for isolating and controlling the flow of fluids, gases or chemicals while minimizing the risk of leaks and contamination. If you work in the oil and gas, chemical or power industry, you have probably heard about double block and bleed ball valves before. But do you know what they are exactly? How they work? What benefits they bring to your operations? In this blog post, we will explore 10 facts about double block and bleed ball valves that every engineer should know. From their applications to their maintenance tips, we’ve got you covered! Let’s dive in!

What is a double block and bleed ball valve?

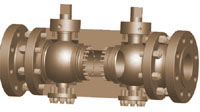

A double block and bleed ball valve is a type of valve that provides two seals against the flow, plus a means of venting pressure between the seals. It consists of two ball valves separated by a cavity or pipe section with a vent valve or drain valve at the bottom. The first ball valve isolates the upstream fluid from the downstream fluid, while the second one isolates the downstream fluid from any residual pressure in between. The cavity in between acts as an extra barrier against leaks.

The main advantage of using double block and bleed ball valves is that they provide redundant protection against leakage, which can be critical for hazardous or costly materials. They also reduce installation costs and space requirements compared to traditional multi-valve systems. Moreover, they save time during maintenance operations since they allow isolation and draining without interrupting production.

Double block and bleed ball valves are commonly used in industries where safety, reliability and efficiency are top priorities such as oil refineries, petrochemical plants, power generation facilities or offshore platforms. In these applications, any failure can lead to catastrophic consequences both financially and environmentally.

Understanding what double block and bleed ball valves are is essential for anyone working with pressurized fluids or gases. By providing dual isolation points coupled with efficient purging capabilities – this design offers unmatched levels of security for sensitive environments around us today!

How does a double block and bleed ball valve work?

A double block and bleed ball valve operates by isolating a section of the pipeline, typically using two ball valves with a cavity in between. The first valve blocks off the fluid flow to one side of the cavity, while the second valve blocks off the opposite side.

The cavity between these two valves can then be drained or vented through a small bleed valve located at its lowest point. This ensures that any fluids or gases trapped within this space are safely released before maintenance work is carried out on either side of the valves.

As an additional safety feature, most double block and bleed ball valves are equipped with automatic pressure relief devices to prevent overpressure build-up within the cavity during operation.

This innovative design allows for increased safety and efficiency in various applications where isolation is critical – from upstream oil & gas production facilities to downstream refineries and chemical processing plants.

The advantages of double block and bleed ball valves

Double block and bleed ball valves offer several advantages over other types of valve configurations. Firstly, they provide a high level of safety by reducing the risk of leaks and ensuring that hazardous materials are contained within the system. This is because double block and bleed ball valves have two separate seals that isolate each side of the valve from one another.

Secondly, these valves are much more compact than traditional multiple-valve systems, which require additional space and installation time. With a double block and bleed ball valve, you can save both time and money on installation costs.

Thirdly, these valves can help reduce maintenance costs since they only require minimal upkeep when compared to other systems like gate or globe valves. They also tend to last longer due to their durable construction.

Double block and bleed ball valves allow for easier control over fluid flow rates thanks to their simple design. This gives operators better control over processes while minimizing downtime needed for repair or replacement.

There are many benefits associated with using double block and bleed ball valves in industrial applications where safety is critical – making them an ideal choice for those looking for reliable fluid management solutions.

The disadvantages of double block and bleed ball valves

Despite their numerous advantages, double block and bleed ball valves also have some disadvantages that you should consider before selecting them for your application.

One of the main disadvantages is their complexity. Double block and bleed ball valves have multiple components, which can make them difficult to install and maintain. They may require special tools or training to properly handle.

Another disadvantage is their higher cost compared to other types of valves. Due to their design and additional features, double block and bleed ball valves can be more expensive upfront than traditional single or double isolation valves.

Additionally, double block and bleed ball valves may not be suitable for applications with high flow rates or high pressure drops. The valve’s design can create turbulence within the pipeline that could impact performance in these scenarios.

It’s important to note that proper maintenance is crucial for ensuring the longevity of a double block and bleed ball valve. Regular inspections are necessary to identify any potential issues before they become major problems.

While there are certainly drawbacks associated with using a double block and bleed ball valve, they remain an excellent choice for many industrial applications where safety and reliability are top priorities.

Double block and bleed ball valves in the oil and gas industry

The use of double block and bleed ball valves in the oil and gas industry is extremely important. These valves provide a safe and reliable way to isolate fluid flows, which can prevent dangerous accidents from occurring.

In the oil and gas industry, double block and bleed ball valves are often used for applications such as pipeline transportation, production isolation, metering systems, and storage tank protection. They are also commonly used in offshore drilling rigs where safety is of utmost importance.

One of the key advantages of using these valves in the oil and gas industry is that they allow for easy maintenance by providing access to each side of the valve without having to shut down an entire system. This means that inspections or repairs can be carried out with minimal disruption to operations.

Another advantage is that double block and bleed ball valves reduce the potential for leaks by providing two separate seals between upstream and downstream fluids. This greatly reduces environmental risks associated with spills or contamination.

However, it’s important to note that selecting the right type of double block and bleed ball valve for each application is crucial. Factors such as pressure ratings, temperature ranges, materials compatibility must all be considered when choosing a valve.

There’s no denying how vital double block and bleed ball valves are within the oil & gas sector. By ensuring enhanced levels of safety whilst offering ease-of-use during maintenance checks; they’re integral components across numerous processes throughout this essential global sector.

Double block and bleed ball valves in the chemical industry

Double block and bleed ball valves are commonly used in the chemical industry due to their ability to isolate and control fluid flow. These valves allow for safe and efficient transfer of hazardous chemicals by providing a double barrier against leakage or contamination.

In addition, double block and bleed ball valves can be designed with materials that are resistant to corrosive chemicals, making them ideal for use in harsh chemical environments. They also have a low torque operation, allowing for easy opening and closing even when handling high-pressure fluids.

These valves play an important role in preventing cross-contamination between different chemical streams during production processes. With their ability to provide isolation on both upstream and downstream sides simultaneously, they ensure that each stream remains pure without any unwanted mixing.

Another advantage of using double block and bleed ball valves in the chemical industry is increased efficiency. These valves reduce the number of connections needed which lowers installation time while reducing potential leak points which increases productivity.

Double block and bleed ball valves are essential components within the chemical industry as they provide improved safety measures while maintaining efficient operations throughout various stages of production processes.

Double block and bleed ball valves in the power industry

Double block and bleed ball valves also play a crucial role in the power industry. Power plants use these valves to isolate different sections of their systems for maintenance, repair, or replacement purposes. These valves ensure that no fluid or gas flows into isolated areas while work is being carried out.

In addition to isolation, double block and bleed ball valves are also used in emergency shutdown situations where they can quickly stop the flow of hazardous materials in case of an accident or malfunction.

Furthermore, power plants require reliable and durable equipment due to their critical nature. Double block and bleed ball valves provide this reliability with their sturdy design and high-performance capabilities under extreme conditions.

As power plants continue to evolve toward more sustainable energy sources such as wind turbines and solar panels, double block and bleed ball valves will still be a necessary component for maintaining safety protocols during operation.

Double block and bleed ball valves offer essential services within the power industry by ensuring safe operations during both routine maintenance tasks as well as emergency situations.

How to select the right double block and bleed ball valve for your application

Selecting the right double block and bleed ball valve for your application is crucial to ensure efficient and safe operations. Here are some factors to consider when choosing a double block and bleed ball valve:

Firstly, consider the pressure rating of the valve. Make sure that the pressure rating is suitable for your application to prevent any accidents or leaks.

Secondly, choose a valve material that is compatible with your process fluid. Different materials have varying corrosion resistance properties, temperature limits, and chemical compatibility.

Thirdly, check the sizes of both inlet and outlet ports. The size should be appropriate for your piping system to avoid flow restrictions or inefficiencies.

Fourthly, consider whether you need manual or automated valves depending on operational requirements.

Evaluate environmental conditions such as temperature extremes or corrosive atmospheres that may affect the performance of the valve over time.

By taking these factors into consideration while selecting a double block and bleed ball valve for your application will help ensure optimal performance in terms of safety and efficiency.

Double block and bleed ball valve maintenance and troubleshooting

Double block and bleed ball valves require regular maintenance to ensure they perform effectively. It is essential to follow the manufacturer’s guidelines for maintenance, which includes cleaning, lubrication and inspection.

The valve should be inspected for any signs of corrosion, wear or damage. If there are any visible issues, the valve may need to be repaired or replaced. The seals on the valve should also be checked regularly as they can deteriorate over time and affect performance.

During routine maintenance checks, it is important to test the integrity of the double block and bleed function by closing both isolation valves while leaving the bleed open. This will confirm that both upstream and downstream pressure has been relieved before performing any work on equipment in between them.

If a problem does occur with a double block and bleed ball valve, it is crucial to troubleshoot it quickly before further damage occurs. Common problems include leaks due to damaged seals or gaskets, critical failure such as broken stem or balls stuck in position.

Proper maintenance of double block and bleed ball valves ensures their longevity and reliable operation whilst troubleshooting identifies problems early enough for quick resolution thereby avoiding more serious equipment failures down-the-line.

Conclusion

To sum up, double block and bleed ball valves are crucial components in industries where safety is a top priority. They offer greater control and reliability over traditional valve systems by isolating fluid flow with two seating surfaces that can be bled to verify the seal integrity.

With their versatility and effectiveness, they have become increasingly popular in various industries such as oil and gas, chemical processing, power generation, and more. It’s vital to consider multiple factors when selecting the right double block and bleed ball valve for your application to ensure optimal performance.

Regular maintenance of these valves is also essential in preventing leakage or other failures that could lead to undesirable consequences. A well-maintained valve will provide years of reliable service while enhancing system safety.

Double block and bleed ball valves are an excellent option for applications requiring tight shut-off capabilities combined with high process integrity. These versatile devices have proven themselves effective at ensuring product quality while increasing efficiency across a range of industrial applications.